Molded Rubber Seals

At Allied Metrics O-Rings & Seals, we are a full-service manufacturer and distributor of hydraulic, pneumatic, and oil seals. We offer a broad selection of quality sealing products, including, but not limited, to custom molded rubber seals.

What Are Molded Rubber Seals?

As suggested by their name, molded rubber seals are seals created through the rubber molding process. The process turns uncured rubber or other elastomeric materials into the desired parts and products by pressing and processing them in specializing molding cavities. In addition to seals, other typical components made through rubber molding include bellows, boots, diaphragms, hoses, and plugs.

Types of Rubber Molding Processes

Rubber molding is an umbrella encompassing a variety of molding techniques. Some of the most commonly used rubber molding methods include:

Compression Molding

This molding method uses a combination of heat and pressure to press the raw material into the mold and form the desired component(s). Once the material has cooled sufficiently, the component is removed from the mold and trimmed to remove excess material (i.e., flash).

It is a cost-effective option for high-volume production. It accommodates high mold cavity density, which helps reduce production time and, consequently, production costs. Additionally, it allows for minimal material loss since the material is placed directly into the mold cavity. However, the process is not suitable for complex and intricate part designs since it cannot achieve tight tolerances and requires precise and accurate placement of the material in the mold.

Injection Molding

The molding method involves heating the material and injecting it in its molten state into the mold cavity. Once the material has cooled sufficiently, the component is removed from the mold and trimmed to any flash present.

It is a suitable manufacturing solution for components that require tight tolerances. It also readily accommodates automation, which can make it much faster than other molding methods. However, it comes with higher tooling costs and smaller mold cavity density capacities, both of which can increase its cost. Additionally, it carries a greater risk of contamination and, when unheated runners are used, material waste.

Transfer Molding

This molding method—also referred to as overmolding—is used to bond rubber to a manufactured metal or plastic component. The material is heated and injected into the mold, which contains the component.

It is an ideal solution for reducing assembly costs. Additionally, its high mold cavity density capacity and short cycle time make it suitable for producing larger quantities of components. However, the complexity of the equipment can result in greater tooling costs, maintenance requirements, and material loss.

Advantages of Molded Rubber Seals

Molded rubber seals offer a number of advantages over other types of seals, such as:

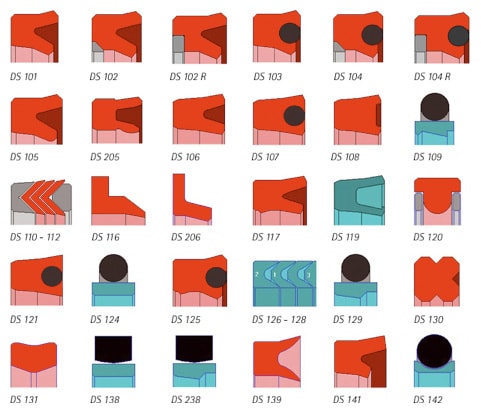

- Broader design flexibility. The rubber molding process can be used to form rubber into a variety of seal shapes to suit different applications.

- Better durability. The properties of rubber enable components made out of the material to return to their original shape after being compressed or otherwise deformed once they’ve been cured. The material can retain this elasticity in many conditions, including hot and cold, depending on the formulation.

- Wider chemical resistance. Many rubbers exhibit resistance to various chemical compounds, such as ammonia, acetaldehyde, acetamide, hydrocarbons, petrochemicals, and more.

- Faster and cheaper production. Rubber and other elastomers are inexpensive to source and easy to form, which allows for cheaper and faster seal production.

Material Options for Molded Rubber Seals

Molded rubber seals can be made from a wide range of materials, each of which has different properties that make it suitable for particular applications. Some of the most commonly used rubbers include:

- AFLAS

- ACM

- Butyl, includes butyl rubber (IIR)

- Chloroprene (Neoprene)

- Epichlorohydrin (CO, ECO, GECO)

- Ethylene-Propylene (EPDM)

- Fluorocarbon (Viton, FKM)

- Fluorosilicone Rubber (FVMQ)

- Nitrile, includes Hydrogenated Nitrile (HNBR) and Carboxylated Nitrile (XNBR) – FDA & Standard

- NBR – FDA & Standard

- VITON – FDA & Standard

- Perfluoroelastomer (FFKM)

- Polyurethane (AU, EU) – Hydrolysis-Resistant, High & Low Temperature-Resistant.

- PTFE (Teflon) – Virgin, Glass-Filled, Bronze-Filled, Carbon-Filled, Graphite-Filled, Ekonol

- Silicone (VMQ) – FDA & Standard

- Styrene-Butadiene Rubber (SBR)

- Other Materials on Request. Please Call Us for Availability.

Molded Rubber Seal Considerations

While the broad selection of rubber seal materials makes it possible for industry professionals to choose a material that suits their exact needs, it also makes it more challenging to find the right one. The best material depends on the product and application. For example, medical device seals come with different requirements and restrictions than automotive seals. Some of the factors to consider when choosing a seal material include:

- Overall production budget

- Environmental conditions

- Operating conditions (e.g., max/min temperature)

- Industry standards

Quality Molded Rubber Seals From Allied Metrics O-Rings & Seals

For molded rubber seals you can trust for your most critical applications, turn to the experts at Allied Metrics. Equipped with extensive seal manufacturing experience and state-of-the-art machining capabilities, we can produce seals to detailed specifications for virtually any need. We manufacture and distribute seals for the aerospace, food processing, oil and gas, and many other industries.

Contact us today to learn more about our molded rubber seal products and services. To discuss your requirements with one of our experts, request a quote.

Available Materials Include:

- NBR – FDA & Standard

- VITON – FDA & Standard

- SILICONE – FDA & Standard

- EPDM

- H-NBR – FDA & Standard

- POLYURETHANE – Hydrolysis-Resistant, High & Low Temperature-Resistant.

- AFLAS

- PTFE – Virgin, Glass-Filled, Bronze-Filled, Carbon-Filled, Graphite-Filled, Ekonol

- Other Materials on Request. Please Call Us for Availability.

Special Uses

Request a quote to place an order or contact us for more information.