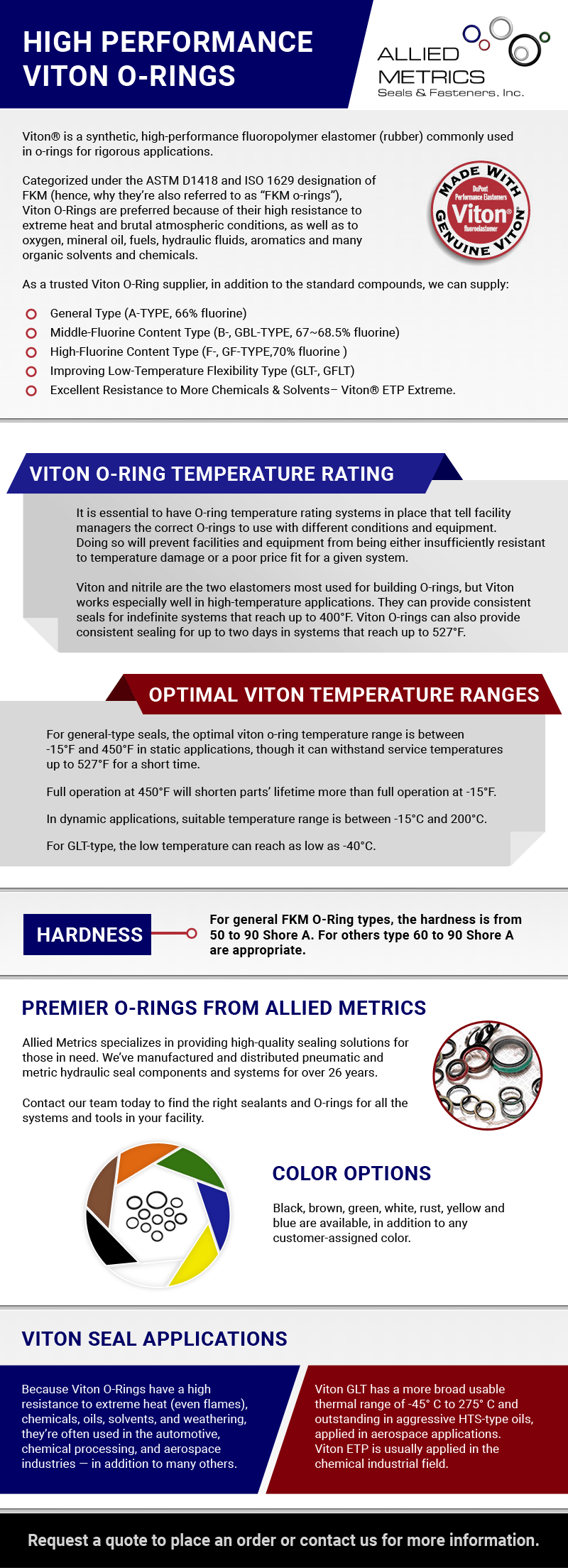

Viton® is a synthetic, high-performance fluoropolymer elastomer (rubber) commonly used in o-rings for rigorous applications. Categorized under the ASTM D1418 and ISO 1629 designation of FKM (hence, why they’re also referred to as “FKM o-rings“), Viton O-Rings are preferred because of their high resistance to extreme heat and brutal atmospheric conditions, as well as to oxygen, mineral oil, fuels, hydraulic fluids, aromatics and many organic solvents and chemicals.

As a trusted Viton O-Ring supplier, in addition to the standard compounds, we can supply:

- General Type (A-TYPE, 66% fluorine)

- Middle-Fluorine Content Type (B-, GBL-TYPE, 67~68.5% fluorine)

- High-Fluorine Content Type (F-, GF-TYPE,70% fluorine )

- Improving Low-Temperature Flexibility Type (GLT-, GFLT)

- Excellent Resistance to More Chemicals & Solvents– Viton® ETP Extreme.

Viton O-Ring Temperature Rating

O-rings are used in seals that have to maintain consistent performance in the face of a wide range of temperature extremes. Industries from aerospace to oil refining have systems in place that reach high temperatures, which can destroy or degrade seals quickly.

For this reason, it’s essential to have O-ring temperature rating systems in place that tell facility managers the correct O-rings to use with different conditions and equipment. Doing so will prevent facilities and equipment from being either insufficiently resistant to temperature damage or a poor price fit for a given system.

Viton and nitrile are the two elastomers most used for building O-rings, but Viton works especially well in high-temperature applications. They can provide consistent seals for indefinite systems that reach up to 400°F. Viton O-rings can also provide consistent sealing for up to two days in systems that reach up to 527°F.

Optimal Viton Temperature Ranges

- For general-type seals, the optimal viton o-ring temperature range is between -15°F and 450°F in static applications, though it can withstand service temperatures up to 527°F for a short time.

- Full operation at 450°F will shorten parts’ lifetime more than full operation at -15°F.

- In dynamic applications, suitable temperature range is between -15°C and 200°C.

- For GLT-type, the low temperature can reach as low as -40°C.

Viton O-ring seals are the preferred material for systems that regularly reach these temperature extremes. Not only do these parts need to withstand high temperatures, but they also must hold up against corrosive chemicals and minerals. Their most common applications are in the following industries:

- Aerospace

- Heavy-duty trucking

- Transportation

- Appliances

- Electronic processing

- Food and beverage processing

- Oil and gas drilling

Within these and other industries, O-rings are frequently used for:

- Boilers, heat exchangers, and heaters

- Compressors, pumps, and valves

- Engines

- Refrigerators

Hardness

For general FKM O-Ring types, the hardness is from 50 to 90 Shore A. For others type 60 to 90 Shore A are appropriate.

Viton vs. Nitrile O-Rings

Nitrile is another material that is commonly used to fabricate O-rings. This material is also called Buna or NBR. Just like Viton, this elastomer has good compression set resistance. However, although nitrile does not function as well as Viton at extremely high temperatures, it performs better at temperatures as low as −65°F.

Nitrile O-rings are best suited for general applications that maintain low temperatures as well as systems that are sealed or protected from the elements and UV radiation. This material is also highly resistant to physical abrasion damage.

However, Viton offers a number of advantages over nitrile in many scenarios. Viton can resist a wide range of corrosive threats that nitrile can’t handle. It holds up very well against acidic and petroleum-based compounds ranging from polymers to auto fuel. Viton also resists oxidation, ozone, and mold, as well as ultraviolet rays and adverse weather conditions.

Many industries use a combination of Viton and nitrile O-rings to seal systems. Many manufacturers default to nitrile O-rings because this material is more affordable, but in doing so, they miss out on the unique advantages Viton brings to the floor.

Facility managers and maintenance crews use Viton O-rings to seal specialty valves and gaskets as needed. Knowing which O-ring is the best choice in different scenarios can help facilities keep costs down without sacrificing safety or quality assurance.

Premier O-Rings from Allied Metrics

Allied Metrics specializes in providing high-quality sealing solutions for those in need. We’ve manufactured and distributed pneumatic and metric hydraulic seal components and systems for over 26 years.

Contact our team today to find the right sealants and O-rings for all the systems and tools in your facility.

Color Options

Black, brown, green, white, rust, yellow and blue are available, in addition to any customer-assigned color.

Viton Seal Applications

Because Viton O-Rings have a high resistance to extreme heat (even flames), chemicals, oils, solvents, and weathering, they’re often used in the automotive, chemical processing, and aerospace industries — in addition to many others. Viton GLT has a more broad usable thermal range of -45° C to 275° C and outstanding in aggressive HTS-type oils, applied in aerospace applications. Viton ETP is usually applied in the chemical industrial field.

| Recommended Applications | Unsuitable Applications | Mechanical Properties |

|---|---|---|

Recommended Applications

|

Unsuitable Applications Ketones (MEK) Auto & Aircraft Brake Fluids Amines (Ammonia) Acetone, Skydrol, Ethyl Acetate Hot Water & Steam (except specialty grades) Low Molecular Esters & Ethers | Mechanical Properties Good Wear Resistance Excellent Comp. Set Resistance Moderate Short-Term Resilience Excellent Permeation Resistance |

Request a quote to place an order or contact us for more information.